Felt TA FRD Aero Test Session with Velo News

It is April 1 2, 2017 and I’m about to aero test the latest Felt TA FRD, reportedly the fastest track frame in the world. I’ll be riding dozens of 30mph laps around the Velo Sports indoor velodrome in Carson, California. I was personally invited by Felt, as the only retailer representative, to test the bike as leaders in the industry looked on.

2, 2017 and I’m about to aero test the latest Felt TA FRD, reportedly the fastest track frame in the world. I’ll be riding dozens of 30mph laps around the Velo Sports indoor velodrome in Carson, California. I was personally invited by Felt, as the only retailer representative, to test the bike as leaders in the industry looked on.

How Did I Get Here?

I started field testing aero setups on my own over fifteen years ago. I was on my Cervelo P3 Aluminum with a PowerTap wheel and I would collect data runs for aero testing early in the morning in a variety of methods. I made countless trips in full aero-get up, various length stem arrangements, different helmets and gear, packed away and stashed to test again and again. I’d test in the rain and with freezing hands in the cold. As the years passed, I improved my position and testing methods and added over 3mph of speed (with no increase in power) along the way. I also started competing on the track and had some results to show for my efforts on the national and world stage.

Today, testing the new Felt TA FRD feels like a culmination of a lot of years of focus and effort. I’m riding and aero testing a bike I could only read about until now. I’m literally testing the fastest equipment the industry has in front of the biggest players. It’s a bit surreal, but it seemed right. I was proud to be here and looked forward to the testing.

Felt TA FRD Design Validation

On this trip, in addition to aero testing, I spent two days learning about every feature that went into the Felt TA FRD superbike from the very people who designed it.

Felt spent two years designing the fastest bike capable of traveling 4km counterclockwise in a velodrome. The bike didn’t have to climb, it didn’t have to corner, and it didn’t have to accommodate a wide range of wheels and components typical for other bikes. This bike wouldn’t see crosswinds, but was designed around the zero to slight left yaw angle seen while riding indoor velodromes. Asymmetrical tubing shapes and component placement are used throughout the bike based on CFD modeling showing optimal aerodynamic drag for these conditions.

Aerobar setups on the Felt TA FRD are 3D printed to match a rider’s fit coordinates ahead of time. We shipped my current bike to Felt in advance of testing so they could match my exact position on the superbike. The exact wheels and tires to be used were designed and modeled into the frame and fork. Hed Cycling designed the

double disc tubular wheelset and tire setup to be as fast as possible in this frame using this same approach. The Felt TA FRD shows integrated design at its current pinnacle in the bike industry.

The result of the Felt TA FRD aero testing and design work was first showcased in the 2016 Rio Olympics. Validation was immediate as the US women lowered the world record in the team pursuit on the way to a silver medal. They’ve since won world titles in both the team and individual pursuits just last week.

Now it is “go time” for me on the Felt TA FRD.

Felt TA FRD Aero Test Staff

Velo News’s Chris Case and Dan Cavallara are track side reporting on the bike and this test session. Chris and Dan spent two days reporting on everything from Felt’s en gineering that went into this frame to today’s testing. Every meal with these guys was like having a built in comedy hour. I look forward to the results they will write about for the industry.

gineering that went into this frame to today’s testing. Every meal with these guys was like having a built in comedy hour. I look forward to the results they will write about for the industry.

Jim Manton from ERO Sports is recording my runs with the Alphamantis TAS system. Jim’s aero tested more pro cyclists, triathletes, and world champions than I can count. He’s seen as many test results that he can’t talk about publicly as those he can at this point. Every lap gives him an immediate aerodynamic drag value, “CdA” in aero geek terms. He will know my drag results as I whip past his table full of computers each lap in real time; he will know how the drag of this bike matches up against that of my existing setup before I do.

Surrounding Jim’s table are a team of Felt’s engineers, mechanics, and staff eagerly looking on. The stage set, I clip in.

Felt TA FRD Aero Test Session 1

Cameras flash as I make my way around the track. The flashes aren’t for me though, but for the amazing new Felt TA FRD that I was now riding. My only job now is to ride smooth laps and hold my position, as I’d done on my existing track bike earlier to establish baselines. Finally, after about a dozen circles, I got the one more lap signal. I sat up to coast down.

I hear “Nineteen!” being yelled repeatedly as I cool down. I’m not sure what that number represents yet, but Jim Manton is shaking his head and looking at me as if s omething is wrong. Nothing was wrong as his head shake turns to a smile.

omething is wrong. Nothing was wrong as his head shake turns to a smile.

Felt’s aerodynamic design and modeling lead Anton Petrov is quietly smiling. He’d spent years working on this bike. Felt’s Jake Duehring is smiling and pointing at me as if to say, “I told you so.” Jake, a recently retired pro track cyclist with a number of elite titles, had tested the new Felt TA FRD last year. I had joined him and the Felt staff on a Pacific coast ride the day before and he told me to expect 1 second per kilometer speed gains on this bike compared to my existing Felt Tk1. Jake repeated, “Your CdA is 0.19!”.

It still didn’t settle in fully. Really? I tested repeated runs of the same position, but on my existing Felt TK1, moments before at a 0.216 CdA. Something was either very wrong or very right. With this much experience smiling at me, I thought it was likely the latter.

Jim’s monitor confirmed the CdA value the Alphamantis TAS equipment had just recorded when all my laps were averaged. Almost everyone had gathered and no one could believe the readings. They even admitted that they didn’t believe my 0.216 value from earlier since it was so low for a guy my size. I volunteered the fact that I’ve spent 15 years testing and refining my position and that the existing bike CdA values they were getting were confirmed two months ago when we tested at ERO’s Milton Ontario velodrome location.

There was still a hint of disbelief in the group as the focus shifted from the bike to the rider. My SRM power meter must be under reporting power as there’s no way a 6’3 broad shouldered former rower weighing 210 lbs could have a CdA that low. “I’ve never seen a guy your size with drag that low.”, Jim repeated skeptically. Despite testing the world’s top pro cyclists and triathletes over the past decade, he had every right to doubt. But he didn’t know how much work I’ve put into this.

To me, in this moment, my position and the Felt TA FRD super bike were both instantly validated. Awesome.

Felt TA FRD Aero Test Session 2 – Verification

How do you know if the data you just recorded is clean? Test it again. I rode another 12 laps at the lowest effort 30mph I’ve ever done. This time the cameras flashing and video rolling were being shot on both sides of me to help try to understand how a guy my size could get that aero. The results: the same 0.190 CdA value (actually, high 0.18…). Chris repeated what he’d yelled to me in the first session, “Did you hear what I said to you? I said you have the drag of a little girl!”. Track riding a bicycle is one of the few places in life where 6′ 3″ guys strive for such a compliment.

Chris tested the Felt TA FRD after me and his results matched mine. He’d powered his existing TK1 to a very impressive- albeit anecdotally brutal and painful- Amateur Hour Record that I’d enjoyed  reading in Velo News last year. Both of us saw similar CdA reductions comparing the Felt TK1 to the new Felt TA FRD. We had both been taught through the years that you just don’t find those savings switching from one aero bike to another. Yet, the data wasn’t lying. In real terms, this is a savings of over 40 watts at my 3km race speed – about 5 second over 3k.

reading in Velo News last year. Both of us saw similar CdA reductions comparing the Felt TK1 to the new Felt TA FRD. We had both been taught through the years that you just don’t find those savings switching from one aero bike to another. Yet, the data wasn’t lying. In real terms, this is a savings of over 40 watts at my 3km race speed – about 5 second over 3k.

Now, I’ll be the first to point out that we didn’t test for a number of other factors that will contribute to actual real world time savings such as rolling resistance on this track or actual drivetrain losses, but known values were used that allowed us to compare the frames head to head in the interest of time. Each bike also had its own power meter, so as any tester will tell you there’s room for error there too. This all being said, it only takes a fraction of that time savings for me to switch equipment; I’m a believer in the new Felt TA FRD and the aero position that I’ve tested and developed.

This was a very important testing session for Felt and the results validated all their incredible hard work to design the first “no compromise” pursuit bike the world has seen. There was visible relief and quiet celebration from everybody track side at the conclusion of the test.

world has seen. There was visible relief and quiet celebration from everybody track side at the conclusion of the test.

One question still remains for some though. How can a 6’3 tall, 210 pound, broad shouldered guy be that aero? Read some of my other testing reports through the years to learn more and consider coming into Fit Werx for a fitting and we can start optimizing your position…

Thanks for reading,

Dean Phillips

Fit Werx 2

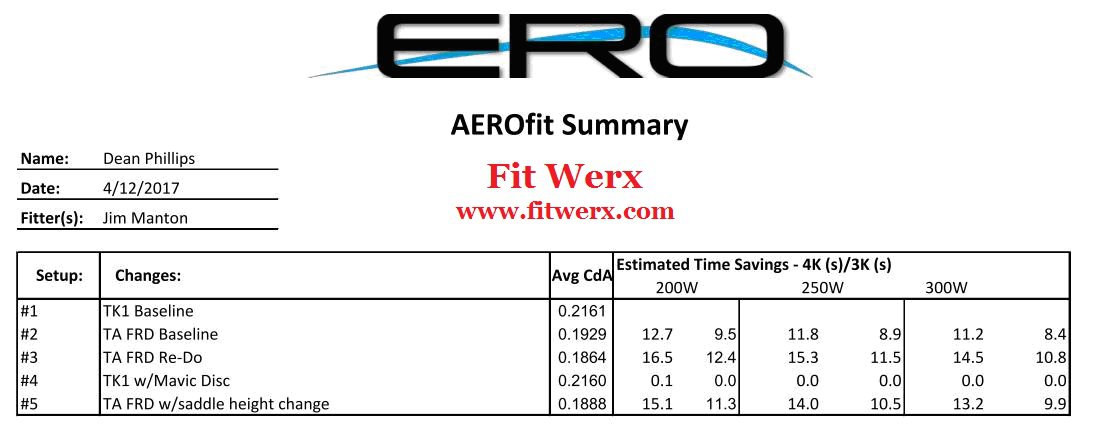

Here are the CdA results for the setups tested. I’d done a second run on the Tk1 and also again on the TA FRD with saddle height adjusted for the crank length. Results were repeatable each time. Note the time savings estimates would be less for me at my 4k/3k speed and power.

Check out the gallery from the session:

[Best_Wordpress_Gallery id=”4″ gal_title=”All Galleries”]