View additional articles and posts on Zipp Wheels.

Few companies have established themselves as category leaders the way that Zipp has in the performance race/event wheel segment. While it may seem like much of this success was a by-product of making strong marketing decisions and having a trendy product, what we like about Zipp is that they keep pushing the innovation envelope. Zipp was acquired by SRAM in late 2007, but they remained focused on building products that excel and the additional resources provided by SRAM have allowed the product durability and development to continue to progress.

A Little Aero Wheel History:

Zipp, along with HED (and Corima in Europe), can really be credited with establishing the aero wheel category in the early 1990’s. In the U.S., Zipp and HED co-hold the original patent on the Toroidal shape that, to-date, remains one of the most aero shape for a rim ever conceived. Zipp honestly could have sat back on the toroidal conce pt and nursed money out of the design for decades – it is that good. However, we like that they did not. Through the years, Zipp engineers have continued to study how the wind relates to bicycle wheels and their wheel products continue to advance because of it. Every year, Zipp engineers keep working to make their rim shape and wheel offerings even better aerodynamically. The introduction of the Firecrest and Firestrike rim designs are testimony to the company’s drive to keep looking forward.

pt and nursed money out of the design for decades – it is that good. However, we like that they did not. Through the years, Zipp engineers have continued to study how the wind relates to bicycle wheels and their wheel products continue to advance because of it. Every year, Zipp engineers keep working to make their rim shape and wheel offerings even better aerodynamically. The introduction of the Firecrest and Firestrike rim designs are testimony to the company’s drive to keep looking forward.

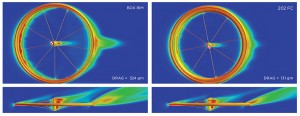

While many wheel companies test their wheels in the wind tunnel, Zipp is one of the few that actually designs their wheels in the wind tunnel. What is the difference? Many wheels are put on the market and then tested in the wind tunnel to see how they perform, Zipp actually uses the wind tunnel to design their wheels. The development of the Zipp 1080 rim design in 2007 is a good example of this. Before even going into the wind tunnel Zipp engineers used wind and road directional data from ac ross the nation to determine what yaw angles (basically, the angle off the front of the object) were most important in cycling. Between the rider’s own speed/momentum, the direction of the road and the way the wind usually blows, the air resistance that slows us down the most tends to hit us at 10-20 degrees of Yaw angle. Based on this, Zipp decided that all of their rim designs should perform optimally in conditions with wind coming from 10-20 degrees of yaw and that is what they went into the tunnel looking to perfect. When the time to go to the wind tunnel came, Zipp brought 43 different wheels in and about a dozen of them were prototype shapes for the new 1080. All were the same 108mm deep, but subtle changes in the bulge shape and placement were tested. While Zipp engineers tested wheels at 0 Yaw (head on), they focused on the data taken from 10-20 degrees primarily and the results were intriguing. What they found was that even very small shifts in the shape and position of the rim bulge in conjunction with how and where they placed their patented Zipp ABLC dimples made a meaningful difference in aerodynamic drag even when the rim depth remained constant. When all was said and done, the design that tested best right in the middle (15 degrees of Yaw) was the end design and what became the 2008 Zipp 1080. When you ride a Zipp wheel, you can rest assured that they are not just wind tunnel tested, but they are designed using the wind tunnel and computational fluid dynamics software to work as optimally as possible across the widest array of likely real world conditions.

ross the nation to determine what yaw angles (basically, the angle off the front of the object) were most important in cycling. Between the rider’s own speed/momentum, the direction of the road and the way the wind usually blows, the air resistance that slows us down the most tends to hit us at 10-20 degrees of Yaw angle. Based on this, Zipp decided that all of their rim designs should perform optimally in conditions with wind coming from 10-20 degrees of yaw and that is what they went into the tunnel looking to perfect. When the time to go to the wind tunnel came, Zipp brought 43 different wheels in and about a dozen of them were prototype shapes for the new 1080. All were the same 108mm deep, but subtle changes in the bulge shape and placement were tested. While Zipp engineers tested wheels at 0 Yaw (head on), they focused on the data taken from 10-20 degrees primarily and the results were intriguing. What they found was that even very small shifts in the shape and position of the rim bulge in conjunction with how and where they placed their patented Zipp ABLC dimples made a meaningful difference in aerodynamic drag even when the rim depth remained constant. When all was said and done, the design that tested best right in the middle (15 degrees of Yaw) was the end design and what became the 2008 Zipp 1080. When you ride a Zipp wheel, you can rest assured that they are not just wind tunnel tested, but they are designed using the wind tunnel and computational fluid dynamics software to work as optimally as possible across the widest array of likely real world conditions.

In 2011, Zipp introduced a new rim shape, Firecrest. Firecrest is one of the most aerodynamic designs on the market and it also dramatically improved handling in crosswinds compared to previous Zipp options. Firecrest was initially used on 404’s and 808’s, both in tubular and carbon clincher versions. In 2012, 303 tubulars and carbon clinchers were added to Firecrest offerings and in 2014 Zipp started offering their limited edition Firestike rims that included next generation rim lay-up and their new Showstopper braking track – possibly the first carbon braking surface to offer better braking in all weather conditions than alloy rims (the Enve SES 2.2 offers similar performing brake technology). Showstopper braking is also available in the ’16 NSW series wheels that also include next generation HexFin ABLC dimpling to continue to further enhance aerodynamics. The 454 NSW, introduced for ’17, continues this progression by adding a new Sawtooth rim design that further enhances aerodynamics while improving stability in sidewinds further. Zipp claims the technology in the 454 NSW can lower drag by up to 20 grams compared to their benchmark 404 due to the extra stability it offers.

In 2011, Zipp introduced a new rim shape, Firecrest. Firecrest is one of the most aerodynamic designs on the market and it also dramatically improved handling in crosswinds compared to previous Zipp options. Firecrest was initially used on 404’s and 808’s, both in tubular and carbon clincher versions. In 2012, 303 tubulars and carbon clinchers were added to Firecrest offerings and in 2014 Zipp started offering their limited edition Firestike rims that included next generation rim lay-up and their new Showstopper braking track – possibly the first carbon braking surface to offer better braking in all weather conditions than alloy rims (the Enve SES 2.2 offers similar performing brake technology). Showstopper braking is also available in the ’16 NSW series wheels that also include next generation HexFin ABLC dimpling to continue to further enhance aerodynamics. The 454 NSW, introduced for ’17, continues this progression by adding a new Sawtooth rim design that further enhances aerodynamics while improving stability in sidewinds further. Zipp claims the technology in the 454 NSW can lower drag by up to 20 grams compared to their benchmark 404 due to the extra stability it offers.

In the past decade, developments in rim width, the addition of a flat braking surface, dimpling, the execution of the unique patented bulge design, and now Firecrest, Firestrike, NSW and Sawtooth have resulted in an even more versatile aero rim shape for all Zipp models. Today, the Zipp 303, Zipp 404 and Zipp 808 continue to be updated annually and remain a standard that other wheels are judged in regards to aerodynamic versatility. Meanwhile, the lightweight and aero Zipp 202 and Zipp 303 show that ultralight and very aero do not have to exist exclusive of one another. The 32mm rim shape found on the Zipp 202 is more aero than some 50mm or deeper wheels while weighing under 1100 grams a pair.

Zipp’s wheel desi gns have always been about aerodynamics while minimizing weight. However, they also realize that a bicycle wheel is a sum of its parts and, if you want to maximize a performance, you need more than just an aero and light rim. Zipp uses high quality hubs with tight tolerances that minimize friction and rolling resistance for this reason. The angular contact steel bearings that Zipp supplies standard with most of their wheels have less rolling resistance than the vast majority of ceramic bearing equipped hubs on the market and a Zipp hub equipped with an ABEC Grade 3 or better ceramic bearing is as smooth as it gets. While a hub design this light and low rolling resistance is not going to be as impervious to water as a higher rolling resistance hub with more friction seals, it is truly superior when it comes to how fast it rolls. In the end, event/race wheels are about speed and Zipp knows all about speedy wheels.

gns have always been about aerodynamics while minimizing weight. However, they also realize that a bicycle wheel is a sum of its parts and, if you want to maximize a performance, you need more than just an aero and light rim. Zipp uses high quality hubs with tight tolerances that minimize friction and rolling resistance for this reason. The angular contact steel bearings that Zipp supplies standard with most of their wheels have less rolling resistance than the vast majority of ceramic bearing equipped hubs on the market and a Zipp hub equipped with an ABEC Grade 3 or better ceramic bearing is as smooth as it gets. While a hub design this light and low rolling resistance is not going to be as impervious to water as a higher rolling resistance hub with more friction seals, it is truly superior when it comes to how fast it rolls. In the end, event/race wheels are about speed and Zipp knows all about speedy wheels.

Zipp wheels and hubs are works of minimalism. Yes, Zipp wheels are cutting edge, but they realize that even a fast event/race wheel is going to be ridden and worked on. Unlike some of their competitors, Zipp did not discard with serviceability and functionality in their pursuit of aerodynamics and light weight. We really like that Zipp does not conceal spoke nipples – concealed spoke nipples have been shown to do little to nothing aerodynamically and it sure is nice when a wheel can be trued without removing the tires. We also like that the cassette bodies are easy to change from Campagnolo to Shimano and the hubs can be taken apart with standard Allen wrenches in a matter of minutes for bearing replacement or service.

Another thing that stands out about Zipp as a dealer is that they truly want to improve and they want feedback. When Fit Werx opened in 2001, we were actually the first authorized and stocking Zipp dealer in all of New England. The first couple years resulted in our harsh New England roads eating more ultra-light carbon rims than we had hoped. The good news was that Zipp noted this too and they sent a representative out to meet and ride with us to find out what could be done. He immediately realized that our roads were a lot rougher than Indiana’s and that Zipp needed to make a change in rim lay-up if they were going to nip the issue. Within three months, Fit Werx was set-up as a test account for a new more durable rim lay-up that Zipp engineers had developed. The test was a grea t success as the number or cracked rims we were seeing from wheels we had sold virtually disappeared. By 2006 Zipp initiated this new generation Carbon Bridge Technology rim design into all of their rims throughout the world. What impressed us was that not many companies the size of Zipp would listen or pay that close attention to a dealer in a remote area of the country, but Zipp did. Since that time, we have been happy to continue to work with Zipp to provide rider and dealer feedback to help improve their products and bring them to the next level.

t success as the number or cracked rims we were seeing from wheels we had sold virtually disappeared. By 2006 Zipp initiated this new generation Carbon Bridge Technology rim design into all of their rims throughout the world. What impressed us was that not many companies the size of Zipp would listen or pay that close attention to a dealer in a remote area of the country, but Zipp did. Since that time, we have been happy to continue to work with Zipp to provide rider and dealer feedback to help improve their products and bring them to the next level.

Outside of their wheel offerings, Zipp also makes handlebars, stems, seatposts and aerobars. We have found these products to be some of the most ergonomically friendly on the market while being strong and light.

So, while Zipp’s aggressive marketing has not hurt, it has little to do with why we carry Zipp wheels. We carry Zipp wheels because of the hard work and dedication that they have made to building some of the fastest and most versatile aero wheels on the planet.

Zipp Wheel Terminology:

ABLC – “Aerodynamic Boundary Layer Control”

You need skin friction drag to minimize much more energy consuming pressure drag. ABLC is the combination of a precise bulged toroidal rim shape in combination with surface variations (like rim dimpling) to create as thin and consistent a layer of skin friction drag as possible against the wheel. This skin friction layer helps keep the air around the wheel calmer and less turbulent and thus minimizes pressure drag. Much like a golf ball, ABLC minimizes turbulence and wind resistance at a variety of yaw (wind) angles through the use of shape and surface structure. Next generation HexFin ABLC dimpling profile is available in NSW wheels as of ’16. Additional information on bicycle aerodynamics can be found in this article.

AeroBalance

The design of a wheel to not just be aerodynamic, but to be aerodynamic and stable simultaneously. Technology like Firecrest and Sawtooth are designed using the Zipp principle of AeroBalance.

Carbon Bridge Technology

The ‘capstone’ on Zipp’s full carbon tubular rims that is created by combining bundles of extra strong Kevlar to the outside of the carbon rim surface. This Kevlar embedded composite structure increases the rims impact resistance without hampering stiffiness at the surface of the rim. Kevlar is not as stiff as carbon, but it is more forgiving while being significantly stronger than steel. Thus, it makes a great material for localized high impact areas (like the contact edge of a bicycle rim) that are under a lot of load and that need to be both strong and forgiving simultaneously. Carbon Bridge Technology allows Zipp to minimize material and weight in-between the two rim sidewalls while making sure that the highest load areas on the rim (at the edges) can absorb impact effectively. The current generation of Carbon Bridge Technology has helped Zipp overcome almost all of the cracking concerns that some of their earlier generation ultralight carbon rims experienced while still maintaining an ultralight design.

Cognition Hubs

Zipp’s highest performance hub technology that is found in NSW wheels. The design minimizes drag by completely disengaging during coasting.

Firecrest Rims

Zipp’s rim profile that uses an almost constant width rim from the spoke bed to the braking track in order to help control air around the back half of the wheel and thus improve aerodynamics while reducing negative handling imbalances placed on the rim from sidewind.

Firestrike Rims

A limited edition top of the line wheel option from Zipp that includes Showstopper braking tracks and ceramic bearing hubs to maximize performance.

Hyperfoil Nodes

Zipp’s patented fin shaped dimpling found on wheels like the 454 NSW that are used in combination with Sawtooth rim design to maximize aero benefit and minimize sidewind distortion.

ICT – “Inversion Composites Technology”

Zipp’s carbon structural rim lay-up process. ICT combines multi-modulus carbon and other composites with a very precise lay-up schedule. Zipp rims combine a monocoque molded radial carbon structure (lightweight and shaped) with unidirectional composite fibers (stiffness and strength) to maximize rim torsional stiffness while simultaneously minimizing weight and maintaining durability.

VCLC – “Viso-Elastic Constrained Layer Control”

Layers of vibration damping materials added into Zipp carbon rim structures that are designed to enhance high frequency vibration damping qualities without compromising stiffness and responsiveness.

Sawtooth

A biomimetic rim design that uses “whale technology” to create a rim shape that is not only more aero on its own than traditional designs, but also more stable in sidewinds (see “AeroBalance”).

Showstopper Brake Track

Zipp’s patented rim brake track that is found on their top of the line wheels (NSW) and is designed to maximize braking power in all conditions, including wet, when used with the co-designed brake pads.

SHIFT – “Spoke Hole Impact Forming Technology”

A focused forging process at the spoke hole designed to minimize stress risers around the spoke hole while aligning the grain structure of the alloy to further maximize strength. Instead of removing material like machining, SHIFT is based on a forging material that compresses and aligns the material. This allows for the minimal weight that makes machining attractive while gaining the stength and durability found in forging to be achieved simultaneously.

Contact Us for more information on Zipp products, to further discuss your wheel purchase, or to order!